Sampling Solutions

Exact Volume Sampling Solutions

New aseptic & accurate sampling solutions from Avantor, designed for your high-value critical samples, are flexible and scalable while reducing contamination risk. What fluid handling solution can we build for you?

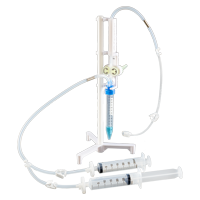

The new adjustable volume sampling system (AVSS) and exact volume sampling system (EVSS) from Avantor® allow customers to aseptically collect samples or transfer critical and high-value products with superior precision. These single-use, closed system, solutions are available as standard products or are fully customizable to your exact specifications. The innovative dual-syringe design provides the ability for users to purge the sampling line easily and reduce product waste. The unique design of the sample conical tube cap creates a closed system, eliminating the need for a biologic hood, meets stringent quality and regulatory standards and minimizes contamination risk — all while maintaining sample accuracy across the entire biopharma workflow.

We focus on creating choice for our customers and removing the barriers of rigid, one-size-fits-all fluid handling design so you can bring critical therapies to market more quickly. AVSS and EVSS are available as standard offerings, and both can be utilized in customizable manifold or quick aseptic connection solutions depending on the sampling requirements of your process.

Precise Volume Sampling Systems, one of many ways Avantor can help you mitigate risk in your high-stakes operations.

- Minimize financial risk with accurate fluid sampling — avoiding product waste of the concentrated and costly samples in cell and gene therapy processes.

- Alleviate production failure by reducing oversampling during the upstream process in cell therapy where less cells are available.

- Maintain sterility in a closed system for a critical end-to-end solution that reduces contamination risk in sensitive workflows.

- Novel, single-use sampling system, available as a standard product or fully customizable to your needs.

Adjustable Volume Sampling System (AVSS)

Avantor’s new AVSS offers significant advantages over traditional sampling methods, particularly for process development and/or small volume transfer.

- Adjustable volume sampling at point of use collecting the volume needed with built in capability to purge excess overdraw and the material in transfer lines back to the source.

- Easy one-step process aseptically evacuates the sample tube completely during transfer, improving product yield without additional sterility risks.

- Offers key quality advantages for critical and high-value products that must meet stringent regulatory standards and creates a cGMP-ready process that maximizes productivity.

- Flexible and scalable design, backed by a robust supply channel network, helps ensure supply chain availability.

AVSS helps our customers overcome complex scale-up challenges, particularly in sensitive applications like cell and gene therapy production and mAbs downstream processing. The single-use sampling device, with reusable adjustment tool and rack, can easily be used stand alone or configured in a manifold — adding quick connection/disconnection technology as needed.

Standard products are available with either PVC (polyvinyl chloride) or TPE (thermoplastic elastomer) inlet tubing enabling weldable connections, minimizing contamination risk while maximizing operational efficiency. AVSS creates a tailored, one-step process unlike any other on the market; reducing process steps and giving your scientists more time for science.

Exact Volume Sampling Solution (EVSS)

The new EVSS from Avantor is best when used at a larger scale, as it can be set to a fixed sampling volume and used repeatedly in a cGMP process. This improves manufacturing consistency and avoids potential sample deviations.

- The standard EVSS can be used as is, or in custom designs to take one or many exact volume samples, depending on your plan requirements. This improves your GMP manufacturing consistency and avoids potential sampling deviations.

- Obtain exact volume samples with precision — increased accuracy in increments of 0.25 ml with tolerance of (+/- 0.25 ml means you only collect the volume needed.

- Innovative dual syringe design allows operators to easily purge the sampling line and minimizes — nearly eliminates — hold up volume and line loss.

- Offers key quality advantages with the elimination of contamination risk; creating a cGMP-ready process to maximize productivity.

- Flexible and scalable design, backed by a robust supply channel network, helps ensure supply chain availability.

The EVSS solution can be customized to your specific process and compliance requirements to overcome fluid handling and sampling pain points. The single-use sampling device, with reusable adjustment tool and rack, can easily be used as is or configured in a manifold — adding quick connection/disconnection technology as needed. Standard products are available with either PVC (polyvinyl chloride) or TPE (thermoplastic elastomer) inlet tubing enabling weldable connections, minimizing contamination risk while maximizing operational efficiency.

Enhance the efficiency of your fluid sampling and transfer process in one step with EVSS and bring breakthrough therapies to market quickly and safely.

OmniTop Assemblies

Avantor OmniTop assemblies offer a wide variety of standard configurations or are custom-designed to suit your specific application. Use OmniTop for the transfer of biopharmaceutical products and reagents in a closed system, gas exchange transfer, sampling of biopharmaceutical products and reagents in a closed system, and storage of biopharmaceutical products and reagents.

- Designed by the fluid experts at Avantor, these assemblies have a proven track record of performance and aseptic fluid sampling and transfer.

- Our open-architecture model creates choice for our customers; configure your assembly with virtually any type of tubing and thermal or RF tubing seals.

- Obtain exact volume samples with our EVSS solution or precise sampling with our AVSS solution that incorporate the OmniTop aseptic tubes, from critical high-value and/or low-volume drug product/substance while maintaining the quality of your product and subsequent samples.

- A closed fluid sampling and transfer system, without the need for a biologic hood, saves time and effort without additional sterility risks.

A comprehensive portfolio of validated, quality products, coupled with our experience across all biopharma platforms, provides the integrated, optimized systems our customers have come to rely on.

Secure your critical, high-value fluids with Avantor’s OmniTop assemblies, and improve product yield by reducing waste for cost-saving benefits.

Customize your sampling solution today

Our closed system sampling solutions are tailored to meet your specific processing needs. An Avantor expert is ready to help design the right system for you. Get started today.

Unparalleled quality you can rely on

ISO certified cleanrooms

Avantor Fluid Handling assemblies are manufactured in an ISO Class 7 (Class 10000) cleanroom.

Certified, compliant & registered

The assembly facility is IS0 -13485 certified and cGMP compliant.

Lot traceability

We offer full lot traceability. Identifying the production site, manufacturing date and origin of components.

Contact an Avantor expert today