Masterflex® Biopharma Application Solutions

Connect with us for single-use simplicity

Get the convenience of our industry-leading expertise, comprehensive product offerings and custom assemblies for complete application workflows

You need to get your single-use bioprocess manufacturing operation running at full optimization. Let Masterflex help you customize biopharma application solutions from our wide range of products.

Choose Masterflex single-use custom disposable sterile assemblies and let us handle:

- Assembling

- Sterilizing

- Validating

You can also opt to select products a la cart to construct your own assemblies. We offer the widest selection of:

- Tubing

- Fittings

- Gaskets

- Sanitary fittings

- Clamps

Along with anything else you may need to keep your bioprocessing workflow running successfully.

We offer custom solutions for your needs

Our experts are here to help you get exactly what you need so you can:

- Minimize cross-contamination risks

- Lower capital investment

- Reduce clean and sterilize steps

- Decrease turnaround times

- Scale an operation up or down with limited additional investment

These are just some of the benefits we offer. Consult with our technical experts to help you get exactly what you need.

Bioprocessing applications rely on Masterflex

Count on Masterflex for the best in biologics equipment. We’re industry leading suppliers of:

- Filtration

- Fluid lines

- Process containment

- Process control

- Cell generation

- Sampling

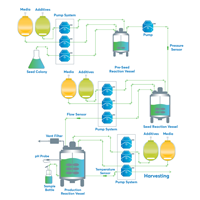

Media Preparation: A vital step in the upstream process

Media prep requires considerable time and effort in cell culture solution preparation with innovative approaches, such as the use of single-use technology, throughout the entire process.

Our peristaltic pumps dose the precise amounts of process nutrients and other media you need via high purity, flexible tubing. They also gently recirculate cells in solution, protecting cell viability.

Fermentation: Growing microorganisms for the biochemical synthesis of organic compounds

Industrial fermentation involves sampling a tank of controlled pH, aeration, agitation and temperature. It requires more preliminary steps than other bioprocess workflows. Common microorganisms used in fermentation include:

- Chinese hamster ovary cells (CHO)

- Yeast

- Fungi

- Bacteria

Masterflex® peristaltic pumps are recommended over diaphragm pumps due to more accurate dosing capabilities and isolated, straight-through fluid path. This makes maintenance easy and minimizes the entrapment of particulates and contaminants.

Harvesting: Collection or clarification of product from fermentation

Typical harvest methods include tangential flow filtration (TFF) or centrifugation as a means of concentrating the target compound. In either of these methods, quality and purity are paramount. Wetted materials (any material touching the fluid) must be validated to USP Class VI requirements and be entirely sterilized.

Peristaltic pumps are ideal for filtration centric workflows, as they’re accurate even at higher pressures.

Purification: Removal of impurities from the harvest and clarification workflows

To remove metals and reaction by-products, scientists rely on affinity and ion-exchange chromatography along with additional methods of filtration. In recent years, and due to demand for higher throughput and versatility, single-use tube component assemblies have become more prevalent.

The isolated fluid flow path of Masterflex peristaltic pumps, is critical to this workflow. These pumps mitigate the potential for contamination and reduce the required material validation.

Fill-Finish: Gently transfer sterile product for packaging or lyophilization

This critical process is closely regulated by a variety of global regulatory and compliance requirements. The sterile product is transferred, in their most valuable form, to a sterile vial or bottle before they are packaged and distributed - or, in many cases, sent to lyophilization (freeze-drying) before they’re packaged.

Peristaltic pumps provide easy changeovers, reduce cross-contamination and gently pump:

- Shear-sensitive fluids

- Large molecules

- Live cells

The valuable end product is contained in the tubing, never touching any part of the pump. Our single-use sterilized assemblies, developed specifically for this process, eliminate downtime for cleaning.

Make your process more efficient today!

- Exactly what you need: Choose from thousands of components. We custom configure, validate and package a wide variety of components according to your precise specifications.

- Exactly when you need it: Stop cleaning and revalidating your system. We manage inventory and ship assemblies according to your preferred schedule.

Call for a quote today. Masterflex single-use experts can give you a quote, including a full schematic, as well as actual samples for your approval.

Let us customize your assemblies

Custom assemblies

Build your own single-use system

Components

Sterilization validtion you can rely on

Validation and packaging