Masterflex® B/T® MasterSense™ BioPharma Process Pump

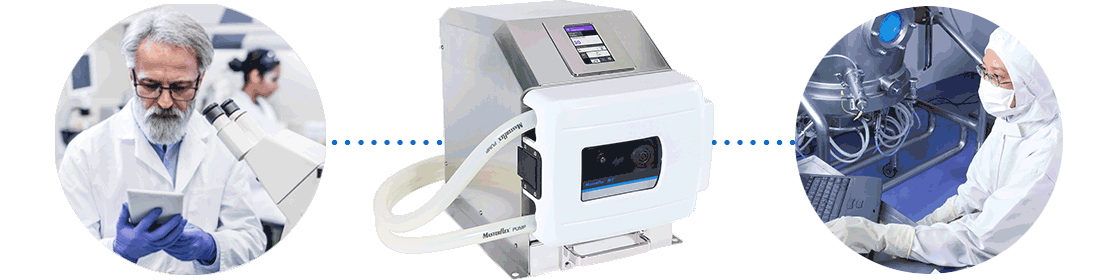

Reimage bioprocessing

NEW integrated sensor technology, intuitive touchscreen and MasterflexLive® remote monitoring for the biopharma industry of tomorrowy

Shop nowConnected, efficient and durable

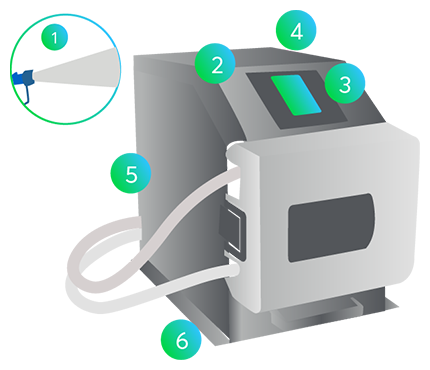

1. Built for high-flow, continuous duty, perfect for sanitary environments— 316 polished stainless steel housing

IP66 rated for washdown

2. Integrated sensors monitor fluid pressure and alert before there is a potential for process failure

3. Intuitive digital touchscreen with optimized menu navigation to store and recall standard protocols ensuring continuity - even with wet gloves on!

4. Over-the-air firmware updates ensure optimization of your pump system without moving the system while MasterflexLive® cloud storage system securely stores, monitors and generates reports for all Masterflex pump systems

5. Variable flow: 0.65 – 42 LPM

VIEW FULL SPECS

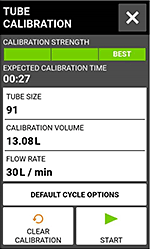

6. Qualitative tube calibration ensures tubing is calibrated precisely – choose PerfectPosition® pump tubiung sizes B/T 87 and B/T 91

SHOP B/T PUMP TUBING

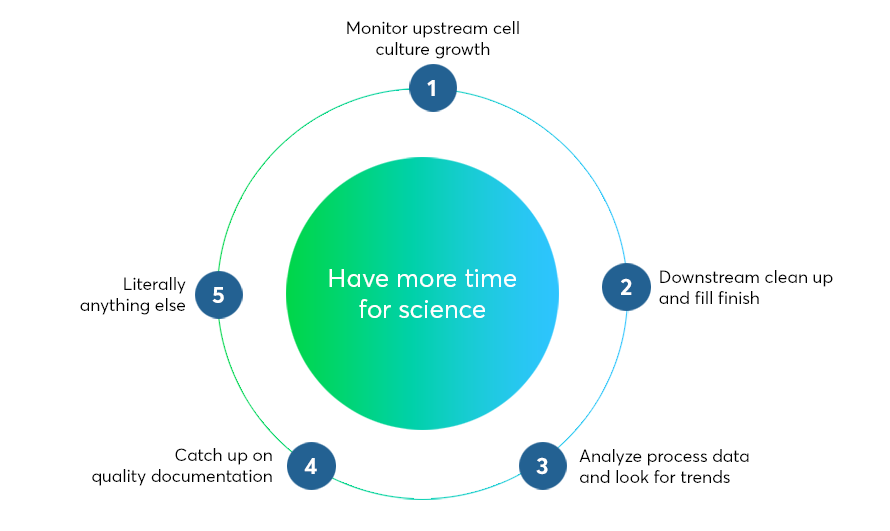

MasterSense™ monitors your media so you don't have to

With the extra time, a process engineer could:

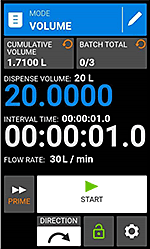

Intuitive Operation

Simple touch screen interface, even while wearing gloves

- Easy to set up and program

- 5" capacitive TFT/RGB touch screen with a clear, wide viewing angle

- Adjust parameters with a simple touch—even with gloves on

- Operational modes include continuous run, volume dispense, and time dispense

- Batch control and interval/off time in Volume and Time modes

- Easily save and recall up to 50 commonly used protocols, each with a unique name

- Know when you hit your mark—graphical indicator lets you know when loaded tubing is optimally calibrated

- IP66 rated for washdown

Continuous Mode

Time Mode

Volume Mode

Remote Mode

Tube Calibration

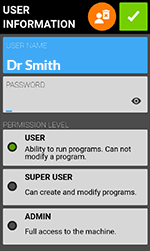

User Access

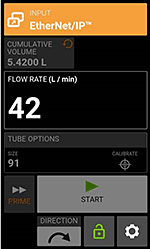

Advanced Connectivity and Control Options

Remote, secure, and in compliance

Remote Monitoring

- MasterflexLive is our secure, cloud-enabled platform for real-time remote monitoring of all Masterflex pump parameters

- Monitor and adjust critical processes running 24/7 without the need for onsite personnel

- Push notifications alert you to changes in operating conditions and error messages

Flexible Connectivity

- Your choice of connectivity options—MasterflexLive, EtherNet/IP, or Profibus

- Three-tier access to pump functionality—use this option to protect your process by controlling who can operate the pump and at what level

- Over-the-air firmware updates—automatically allows you to take full advantage of future enhancements

- Internet connection via Wi-Fi or standard Ethernet (RJ45) jack on rear of drive

The Perfect Pump for High-Volume Applications

IP66 rated- built for sanitary, washdown environments including clean rooms, food, and dairy processing.

Non-contaminating, low shear, and noninvasive makes this pump perfect for Biopharma and healthcare.

Flows up to 42 LPM to ensure precise flow rates making this pump ideal for large-scale production.

Three-tier access and the ability to save and recall programs making your fluidic process secure and accurate.

|

Item # MFLX77112-10 | |||

What's Included Rapid-Load® pump head, 3 ft (1 m) of Tygon® LFL B/T 91 tubing 06430-91; and a 6-ft (1.8-m) line cord with IEC 320/CEE22 socket. Unit is shipped with country specific plug/cord set; please specify ultimate destination when ordering. |

||||

Performance Specifications |

||||

| Flow capacity | 0.65 to 42 LPM (0.17 to 11.1 GPM) | |||

| rpm | 11 to 321 | |||

| Number of heads accepted | 1 | |||

| Maximum torque | Starting: 1130 N•cm (1600 oz-in) | |||

| Running: 1017 N•cm (1440 oz-in) | ||||

| Reversible | Yes | |||

| External control - input | 0 to 20 mA, 20 to 0 mA, 4 to 20 mA, 20 to 4 mA; 0 to 10 V, 10 to 0 V, 0 to 5 V, 5 to 0 V; Start/Stop, Direction (CW/CCW), Prime via contact closure | |||

| External control - output | 0 to 20 mA, 20 to 0 mA, 4 to 20 mA, 20 to 4 mA; 0 to 10 V, 10 to 0 V, 0 to 5 V, 5 to 0 V; Tach output (open collector), Motor running, Open head, Local/Remote, General alarm | |||

| Network communication | EtherNet/IP, Profibus, MasterflexLive | |||

Electrical Specifications |

||||

| Voltage | 90 to 260, universal voltage autoselecting | |||

| Current | 5.0 A at 115 V; 3.1 A at 230 V | |||

| Fuse rating | 6 A / 250 V | |||

| Motor type | Continuous duty, TENV, BLDC | |||

| Motor size | 370 W (0.5 hp) | |||

| Display | 5” capacitive TFT/RGB touch screen with in-plane switching (wide viewing angle); 800 x 480 pixels | |||

| Motor/speed control type | PWM with microprocessor | |||

| Speed regulation (repeatability) | ±0.1% | |||

| Soft start/Electronic brake | Yes/Yes | |||

Physical specifications |

||||

| Housing materials | 316 stainless steel housing, stainless steel chassis, stainless steel bezel | |||

| Pump head materials | Powder-coat carbon steel and cast aluminum, stainless steel, polycarbonate, Nylatron® rollers | |||

| IP rating | IP66 | |||

| Agency listings | UL, cUL, CE, DLS | |||

| Operating temperature | 0 to 40°C (32 to 104°F) | |||

| Storage temperature | -25 to 65°C (-13 to 149°F) | |||

| Noise level | <75 dBA @ 1 m (39") | |||

| Dimensions (L x W x H) | 62.2 x 40.1 x 47.8 cm (24.5" x 15.8" x 18.8") | |||

| Shipping weight | 54.5 kg (120 lb) | |||